Search for:

Mechatronic paths with inconsistent error detection information

Explanation:

The MSR form will be searched for error detections which were assigned inconsistent DC or M values.

An inconsistency is available whenever a DC value of at least 99.99% has been combined with an M value of less than 1. It is just as inconsistent if an M value of 1 has been combined with a DC value of less than 99.99%.

Example:

Abbreviations:

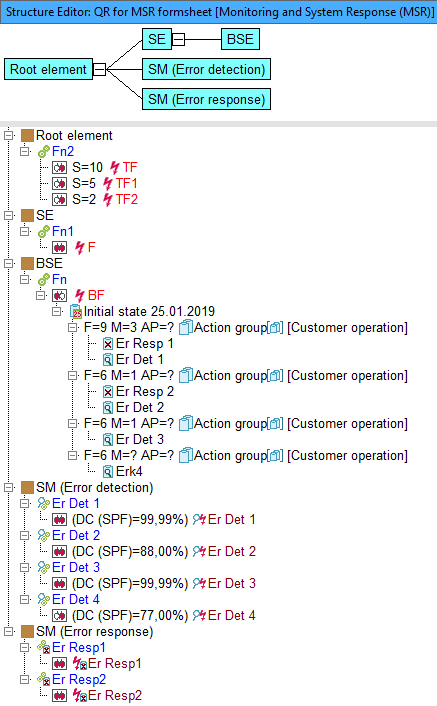

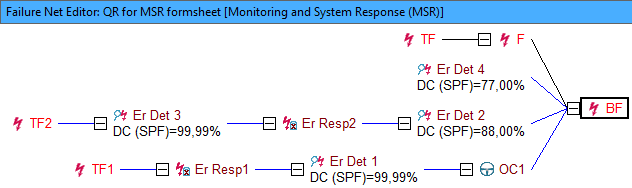

- The example demonstrating how the described quality rule (QR) works has the structure shown above. The contained failures and safety mechanisms are linked with each other as shown in the failure net below. By selecting the appropriate display options (e.g., Functional Safety parameters; Valuation), the parameters that are relevant to the implementation of the QR can be shown in both the Structure Editor and the Failure Net Editor.

- The described QR searches for error detections that have been assigned inconsistent DC and M values. An inconsistency is available if the same error detection has been assigned a DC value of at least 99.99% as well as an M value of less than 1. It is just as inconsistent if an M value of 1 has been combined with a DC value of less than 99.99%.

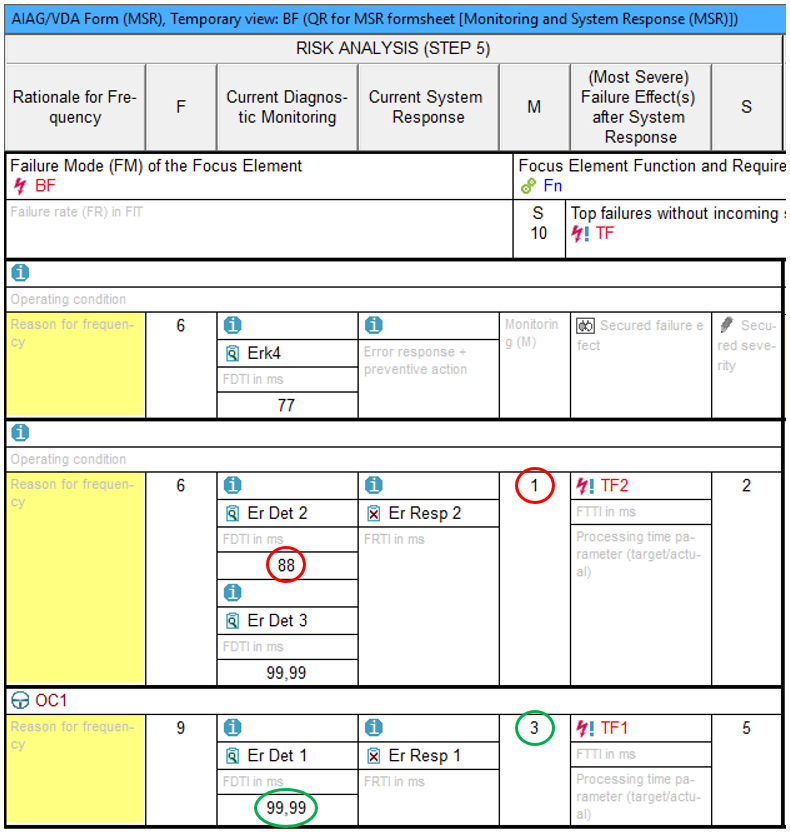

- The described QR can only be performed in the MSR form (RISK ANALYSIS (STEP 5)). Therefore, the QR search result is displayed in the MSR form. The form that has the focus failure BF, looks as follows in our example:

Search result:

The two error detections Er Det 1 and Er Det 2 are shown as valid QR search objects. That can be easily verified because, due to the DC and M values shown in the MSR form, the comparison made in the QR can be visually retraced.